close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

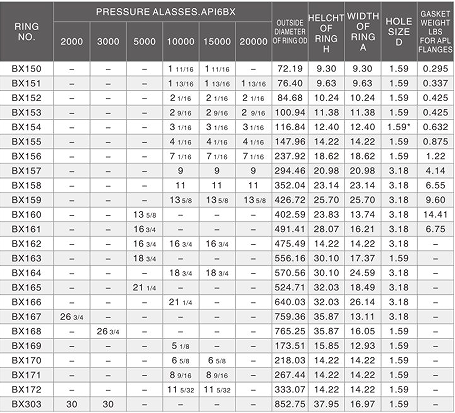

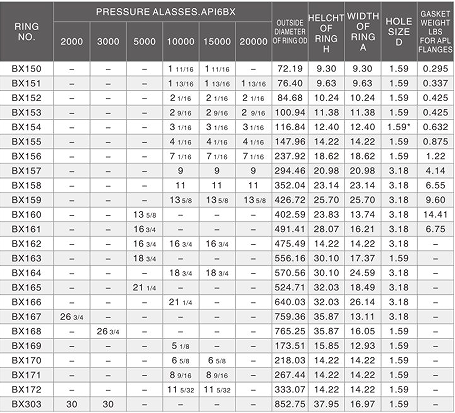

| Size/Pressure Class | 1 11/16” to 30” : ” 2000 to 20000 API 6A |

| Applications | * The Style BX energized ring type joint is manufactured in accordance with API 6Aforuse in high pressures. |

| * Style BX ring type joints incorporate a pressure passage hole to allow for pressure equalization each side of the sealing faces. | |

| * Style BX is not interchangeable with any other style, and is only suited for API 6BX flanges. |

Product Description:

The Ring Joint Gasket is a high-performance sealing solution designed for critical applications in high-pressure and high-temperature environments. Crafted from premium materials such as carbon steel, stainless steel, soft iron, or specialty alloys, these gaskets are engineered to meet the demanding requirements of industries such as oil and gas, petrochemicals, and power generation.

Material Options: Available in carbon steel, stainless steel (SS304/SS316), soft iron, alloy steel, and nickel-based alloys.

Standard Compliance: Designed according to API 6A, ASME B16.20, and ISO standards for precision and reliability.

Pressure Rating: Supports pressure ranges from 2,000 PSI to 20,000 PSI.

Temperature Range: Suitable for applications ranging from -50°C to 800°C (-58°F to 1472°F), depending on material choice.

Types and Sizes: Includes R, RX, and BX series with dimensions customizable to fit various flanges.

Superior Sealing Performance: Metal-to-metal contact ensures a tight, leak-proof seal under extreme conditions.

Durability: High-strength materials resist deformation and maintain integrity over prolonged use.

Corrosion Resistance: Specialty materials and coatings provide excellent protection against corrosive media.

Precision Engineering: Tight manufacturing tolerances guarantee perfect alignment with flanges for optimal performance.

Versatility: Applicable for both static and dynamic sealing in pipelines, valves, and other critical equipment.

The Ring Joint Gasket is ideal for:

Oil & Gas: High-pressure pipelines, wellheads, and Christmas trees.

Petrochemical Industry: Processing plants and storage systems.

Marine Engineering: Offshore platforms and subsea equipment.

Power Generation: Steam turbines and high-temperature boilers.

Certified to API, ISO, and ASME standards for global application.

Comprehensive testing ensures compliance with industry-specific performance and safety requirements.

Non-standard Sizes: Custom dimensions for unique operational requirements.

Special Coatings: Anti-corrosion and high-temperature coatings for enhanced durability.

Material Customization: Tailored material grades for specific environments or media.

Clear installation guidelines to ensure secure, optimal sealing.

Reusable in specific applications, reducing operational costs.

High-Resolution Images: Detailed views of the gasket’s surface, profile, and sealing grooves.

Technical Drawings: Precise dimensional data for engineering applications.

Instructional Videos: Demonstrations of proper installation and performance in action.

Expert Engineering Support: Our team provides tailored recommendations for your specific needs.

Fast Delivery: Comprehensive inventory and streamlined logistics ensure timely fulfillment.

Reliable Quality Assurance: Rigorous testing guarantees every gasket meets the highest standards.

Contact us today to learn more about our Ring Joint Gaskets or to request a quote for your project.

| Size/Pressure Class | 1 11/16” to 30” : ” 2000 to 20000 API 6A |

| Applications | * The Style BX energized ring type joint is manufactured in accordance with API 6Aforuse in high pressures. |

| * Style BX ring type joints incorporate a pressure passage hole to allow for pressure equalization each side of the sealing faces. | |

| * Style BX is not interchangeable with any other style, and is only suited for API 6BX flanges. |

Product Description:

The Ring Joint Gasket is a high-performance sealing solution designed for critical applications in high-pressure and high-temperature environments. Crafted from premium materials such as carbon steel, stainless steel, soft iron, or specialty alloys, these gaskets are engineered to meet the demanding requirements of industries such as oil and gas, petrochemicals, and power generation.

Material Options: Available in carbon steel, stainless steel (SS304/SS316), soft iron, alloy steel, and nickel-based alloys.

Standard Compliance: Designed according to API 6A, ASME B16.20, and ISO standards for precision and reliability.

Pressure Rating: Supports pressure ranges from 2,000 PSI to 20,000 PSI.

Temperature Range: Suitable for applications ranging from -50°C to 800°C (-58°F to 1472°F), depending on material choice.

Types and Sizes: Includes R, RX, and BX series with dimensions customizable to fit various flanges.

Superior Sealing Performance: Metal-to-metal contact ensures a tight, leak-proof seal under extreme conditions.

Durability: High-strength materials resist deformation and maintain integrity over prolonged use.

Corrosion Resistance: Specialty materials and coatings provide excellent protection against corrosive media.

Precision Engineering: Tight manufacturing tolerances guarantee perfect alignment with flanges for optimal performance.

Versatility: Applicable for both static and dynamic sealing in pipelines, valves, and other critical equipment.

The Ring Joint Gasket is ideal for:

Oil & Gas: High-pressure pipelines, wellheads, and Christmas trees.

Petrochemical Industry: Processing plants and storage systems.

Marine Engineering: Offshore platforms and subsea equipment.

Power Generation: Steam turbines and high-temperature boilers.

Certified to API, ISO, and ASME standards for global application.

Comprehensive testing ensures compliance with industry-specific performance and safety requirements.

Non-standard Sizes: Custom dimensions for unique operational requirements.

Special Coatings: Anti-corrosion and high-temperature coatings for enhanced durability.

Material Customization: Tailored material grades for specific environments or media.

Clear installation guidelines to ensure secure, optimal sealing.

Reusable in specific applications, reducing operational costs.

High-Resolution Images: Detailed views of the gasket’s surface, profile, and sealing grooves.

Technical Drawings: Precise dimensional data for engineering applications.

Instructional Videos: Demonstrations of proper installation and performance in action.

Expert Engineering Support: Our team provides tailored recommendations for your specific needs.

Fast Delivery: Comprehensive inventory and streamlined logistics ensure timely fulfillment.

Reliable Quality Assurance: Rigorous testing guarantees every gasket meets the highest standards.

Contact us today to learn more about our Ring Joint Gaskets or to request a quote for your project.